The primary purpose of needle rollers, which, like ball bearings, are referred to as “rolling elements,” is to significantly reduce the friction between the bearing or guiding components in a rolling bearing or linear guide rail. As compared to a cylinder roller, needle rollers are used for structures in which high loads must be compactly distributed.

Translated into our everyday language, this means: Nothing functions without rolling elements and rolling bearings. Cars wouldn’t go, clothes driers wouldn’t run and kitchen machines could not stir. Needle rollers ensure that everything functions perfectly everywhere. The slender rolling elements have a needle-like bearing surface and accept radial or axial loads at more contact points than a precision ball does.

Basic components of needle bearings, needle rollers are primarily used in the automotive, electrical, toy, DIY and household appliance industries, as well as in general mechanical systems. Namely, everywhere that compact, high loads must be transferred. After all, they only require a small installation space.

Bearing or guiding components possess high stability, and needle rollers enable them to be used despite their miniature design. In miniature systems, needle-shaped rollers can also be used as axles or shafts.

Properties:

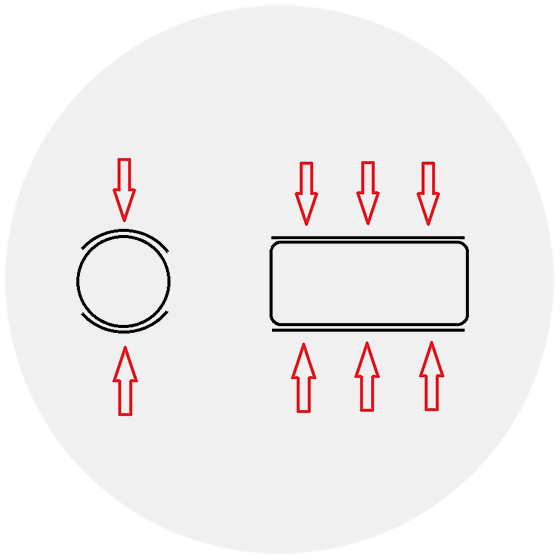

Sometimes only nuances determine which rolling element is better suited to which application. While BALL BEARINGS accept medium to high axial and radial forces, for example, and are used accordingly for medium to high speeds, needle rollers have a high load-bearing capacity.

The geometry of a needle roller comprises an elongated lateral surface and the pounded or smooth front surface. This creates the typical, needle-shaped profile of the rolling element, which can distribute high loads better than a precision BALL BEARING. To determine the quality and range of applications of a needle roller, cylindrical rolling elements are standardised in accordance with DIN 5402.