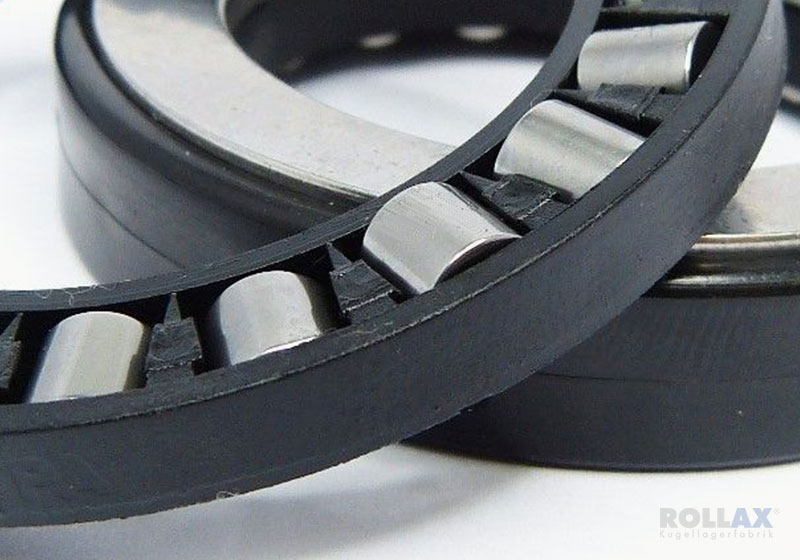

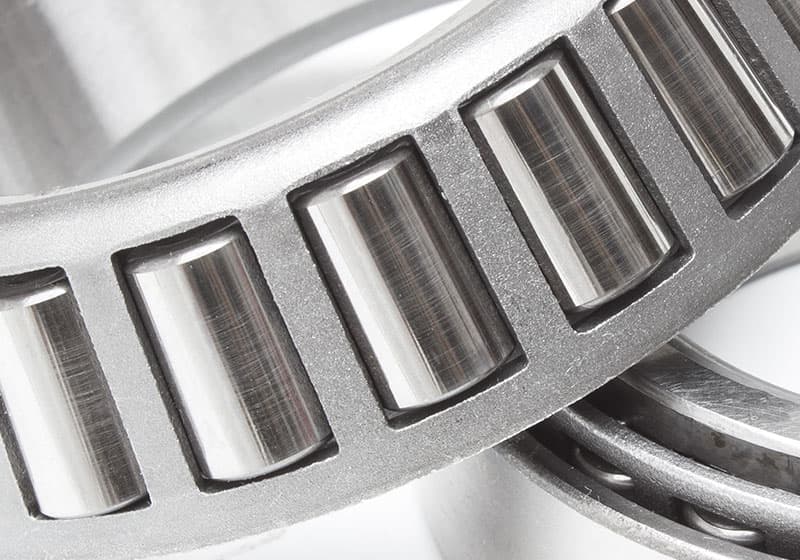

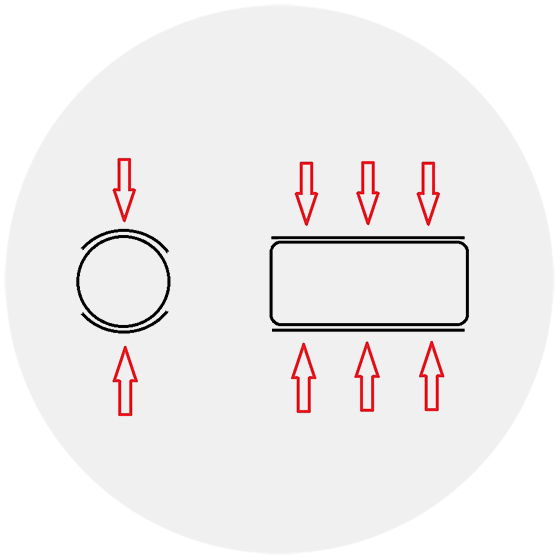

Our cylindrical rollers are ideal for applications that require high radial loads or the ability to withstand impact loads. Likewise, they are suited to components that are subjected to extreme axial forces. To achieve that effect, cylindrical rollers are typically profiled, with or without edges. Compared to precision balls, cylindrical rollers can distribute contact forces over additional areas.

High loads are no problem for these bearings. The geometry of these rolling-element bearings leads to less wear, making them suitable for high-speed applications. To select the right cylindrical rollers for your application, specify the required diameter (measured at the face of the cylindrical roller), for example, and the length, edge, and the material.

Cylindrical rollers are ideally suited for moving high loads or for high radial loads which act upon rolling bearings and other mechanical components. They are distinguished by a superior surface finish, outstanding hardness, and high load capacity. Applications include gear construction and robotics, machine, vehicle and equipment construction and measurement technology, for example. To be more specific, cylindrical rollers are used to transmit forces such as those in axial bearings or heavy-duty drawers.

Properties:

If rolling-element bearings are subjected to high and heavy loads, opt for cylindrical rollers, which can withstand greater loads than similar needle roller bearings. Cylindrical roller bearings absorb axial and radial forces better than ball bearings. For them to have that effect, their shape consists of a longitudinal surface and two end faces, which are logarithmically rounded or unground. These bearings are used to distribute the edge stress of cylindrical rollers differently. To evenly distribute forces, we recommend the use of one each per loaded component.